|

Digital Thickness Meter 101-713

Serials

|

|

Features:

1) ON/OFF Switch |

||||

|

|

|

|

|

| Specifications: | 101-7130/7134 | 101-7131/7135 | 101-7132/7136 | 101-7133/7137 |

| Order No. | Range | Resolution | Throat depth A | Accuracy | Note |

|---|---|---|---|---|---|

| 101-7130 | 0-12.7mm/0.5" | 0.01mm/0.005" | 30mm | ±0.02mm | Stainless Steel Tip |

| 101-7131 | 0-12.7mm/0.5" | 0.01mm/0.005" | 60mm | ±0.02mm | Stainless Steel Tip |

| 101-7132 | 0-12.7mm/0.5" | 0.01mm/0.005" | 120mm | ±0.02mm | Stainless Steel Tip |

| 101-7133 | 0-20.00mm/1" | 0.01mm/0.005" | 120mm | ±0.02mm | Stainless Steel Tip |

| 101-7134 | 0-12.7mm/0.5" | 0.001mm/0.0005" | 30mm | ±0.009mm | Stainless Steel Tip |

| 101-7135 | 0-12.7mm/0.5" | 0.001mm/0.0005" | 60mm | ±0.009mm | Stainless Steel Tip |

| 101-7136 | 0-12.7mm/0.5" | 0.001mm/0.0005" | 120mm | ±0.009mm | Stainless Steel Tip |

| 101-7137 | 0-20.00mm/1" | 0.001mm/0.0005" | 120mm | ±0.009mm | Stainless Steel Tip |

| 101-7130C | 0-12.7mm/0.5" | 0.01mm/0.005" | 30mm | ±0.02mm | Ceramic Tip |

| 101-7134C | 0-12.7mm/0.5" | 0.001mm/0.0005" | 30mm | ±0.009mm | Ceramic Tip |

| 101-7130S | 0-12.7mm/0.5" | 0.01mm/0.005" | 30mm | ±0.02mm | Sharp Tip |

| 101-7134S | 0-12.7mm/0.5" | 0.001mm/0.0005" | 30mm | ±0.009mm | Sharp Tip |

|

Continuous Thickness Meter With

Roller

|

|

Features: 1. Equipped with a shock-proof dial indicator. 2. With roller insert, easy for continuous measurements of thickness of strip plates. 3. Measuring inserts close when not used. |

|

|

||||

| Model | Range | Resolution | L (mm) | Accuracy | ||

| 101-7138 Dial | 0-10mm | 0.01 | 100 | ±20μm | ||

| 101-7139 Digital | 0.01/0.0005" | |||||

|

Digital Thickness Meter TA202

|

|

Features:

1) ON/OFF Switch |

|

|

|

Specifications: Range: 0-10mm/0.4" Resolution: 0.01mm/.0005" Throat depth: 30mm Accuracy: ±0.03mm |

|

Mini Digital Thickness Gauge TA203

|

|

Features:

1) ON/OFF Switch |

|

|

Specifications: Range: 0-12.7mm/0.5" Resolution: 0.01mm/0.0005" Throat depth A: 11mm Accuracy: ±0.02mm |

|

Digital Thickness Gauge TA205

|

|

Features:

1) ON/OFF Switch |

|

|

Specifications: Range: 0-12.7mm/0.5" Resolution: 0.01mm/0.0005" Throat depth A: 11mm Accuracy: ±0.02mm |

|

Digital Thickness Gauge TA206

|

|

Features:

1) ON/OFF Switch |

|

|

Specifications: Range: 0-25.4mm/1" Resolution: 0.01mm/0.0005" Throat depth A: 11mm Accuracy: ±0.02mm |

|

Digital Tube Thickness Gauge TA207,

TA208

|

|

Order Number:

TA207:

0~10mm/0.4" |

|

|

Features:

1) ON/OFF Switch |

|

|

Specifications: Range: 0-10mm/0.4" (TA207), 0-25mm/1" (TA208) Resolution: 0.01mm/0.0005" Throat depth A: 11mm Accuracy: ±0.02mm |

|

Digital Tube Thickness Gauge TA209

|

|

Features:

1) ON/OFF Switch |

|

|

Specifications: Range: 0-15mm/0.6" Resolution: 0.01mm/0.0005" Throat depth A: 11mm Accuracy: ±0.02mm |

|

Coating Thickness Meter AMT15

|

|

Features: 1. Non-magnetic coatings (e.g. paint, zinc) on steel 2. Insulating coatings (e.g. paint) on no-ferrous metals 3. No-ferrous metals coatings on insulating substrates 4. Menu operation system 5. Two measuring mode: CONTINUE and SINGLE mode 6. Two working Mode: DIRECT and GROUP mode 7. Statistic Display: AVG, MAX, MIN, NO., S.DEV 8. One point calibrating, two points calibrating and basic calibrating easily 9. Memory for 400 readings(80 DIRECT and 320 GROUP readings) 10. Delete single readings and all group readings easily 11. High alarm and Low alarm for all working mode 12. Low battery, error indication 13. USB interface for PC software (windows 98/2000/xp/vista) |

|

| Specifications: | |

|

Sensor probe |

F |

N |

|

Working principle |

magnetic induction |

Eddy current principle |

|

Measuring range |

0~1250um |

0~1250um |

|

Guaranteed tolerance (of reading) |

(+/- 3%+1)um |

(+/- 3%+1.5)um |

|

Low range Precision |

0.1um |

0.1um |

|

Minimum curvature radius |

1.5mm |

3mm |

|

Diameter of Minimum area |

3mm |

5mm |

|

Basic critical thickness |

0.5mm |

0.3mm |

|

Size (HxWxD) |

113.5mm x 54mm x 27mm |

|

|

Weight |

110g |

|

|

Coating Thickness Meter AMT15A

|

|

Features: 1. Non-magnetic coatings (e.g. paint, zinc) on steel 2. Insulating coatings (e.g. paint) on no-ferrous metals 3. No-ferrous metals coatings on insulating substrates 4. Menu operation system 5. Two measuring mode: CONTINUE and SINGLE mode 6. Two working Mode: DIRECT and GROUP mode 7. Statistic Display: AVG, MAX, MIN, NO., S.DEV 8. One point calibrating, two points calibrating and basic calibrating easily 9. Memory for 400 readings(80 DIRECT and 320 GROUP readings) 10. Delete single readings and all group readings easily 11. High alarm and Low alarm for all working mode 12. Low battery, error indication 13. USB interface for PC software (windows 98/2000/xp/vista) |

|

| Specifications: | |

|

Sensor probe |

F |

N |

|

|

Working principle |

magnetic induction |

Eddy current principle |

|

|

Measuring range |

0~1300um (0~51.2mils) |

0~1300um (0~51.2mils) |

|

|

Guaranteed tolerance (of reading) |

(+/- 3%+2um) |

(+/- 3%+2um) |

|

|

Resolution |

0~999um |

1um |

1um |

| 1000~1300um | 0.01mm | 0.01mm | |

|

Minimum Max curvature radius |

1.5mm/25mm |

1.5mm/25mm |

|

|

Minimum Diameter of Minimum area |

6mm |

6mm |

|

|

Basic critical thickness |

0.5mm |

0.3mm |

|

|

Size (HxWxD) |

113.5mm x 54mm x 27mm |

||

|

Weight |

110g |

||

|

Mini Film Coating Thickness Meter

AMF066

|

| Measurement

ranges: 0~1.80mm/0~71.0mil Resolution: 0.01mm/1mil Measurement error: ±0.03mm Min. diameter of substrate: 50mm Min. thickness of substrate: 0.5mm Power supply: 2*1.5V AAA batteries Operating temperature range 0~40℃ Operating humidity range: 10~95%RH Overall dimensions: 61.98*30.57*104.99cm Weight: 63.98g Standard Quantity Per Carton: 60PCS Standard Carton Size: 49.7x 49 x 45.3cm |

|

|

Mini Film Coating Thickness Meter

AMF067

|

| Measurement

ranges:0~1800μm/0~70.9mil Resolution:0.1μm/1μm/1mil Measurement error:±(3%H+1μm) Min. diameter of substrate:Φ12mm Min. thickness of substrate:0.5mm Min. curvature radius of convex substrate:2mm Min. curvature radius of concave substrate:11mm Power supply:2*1.5V AAA batteries Operating temperature range 0~40℃ Operating humidity range:10~95%RH Overall dimensions:61.98*30.57*104.99mm Weight:63.98g Standard Quantity Per Carton:20PCS Standard Carton Size:65.9*44*28.9cm |

|

|

Film Coating Thickness Gauge AMF021

|

| *Measuring range:

0~1800µm *Accuracy: ±3%H±1µm *Resolution: 0.1µm (<100µm) or 1µm(>100µm) *Use Hi-sensibility sensor for precise measurement *Zero point, two point and basic, three different calibration *Measuring mode: Single, Continually and Difference *Data store/ Data recall/ Data delete function *Data Analysis: Average, Maximum, Minimum, Standard deviation and measuring times *Beep sound indication *Measure in Metric/Imperial *LCD backlight display *Low battery indication *Auto power off *Packing method: Gift box + PP box *Power supply: 9V battery *Weight: 147g (without battery) *Dimension: 67*30*183mm |

|

|

Film Coating Thickness Gauge AMF022

|

| *Measuring range:

0~1500µm *Accuracy: ±3%H±1µm *Resolution: 0.1µm (<100µm) or 1µm(>100µm) *Use Hi-sensibility sensor for precise measurement *Zero point, two point and basic, three different calibration *Measuring mode: Single, Continually and Difference *Data store/ Data recall/ Data delete function *Data Analysis: Average, Maximum, Minimum, Standard deviation and measuring times *Beep sound indication *Measure in Metric/Imperial *LCD backlight display *Low battery indication *Auto power off *Packing method: Gift box + PP box *Power supply: 3*1.5V AAA battery *Weight: 250g (without battery) *Dimension: 70*145*28mm *Accuracy: ±3%H±1µm |

|

|

Film Coating Thickness Gauge

AMF022F

|

| *Measuring range:

0~1800µm *Accuracy: ±3%H±1µm *Resolution: 0.1µm (<100µm) or 1µm(>100µm) *Use Hi-sensibility sensor for precise measurement *Zero point, two point and basic, three different calibration *Measuring mode: Single, Continually and Difference *Data store/ Data recall/ Data delete function *Data Analysis: Average, Maximum, Minimum, Standard deviation and measuring times *Beep sound indication *Measure in Metric/Imperial *LCD backlight display *Low battery indication *Auto power off *Warranty: 12months *Packing method: Gift box + PP box *Power supply: 9V battery *Weight: 220g (without battery) *Dimension: 70*145*28mm |

|

|

Coating Thickness Meter MCT200

|

| Order Number: MCT200 (with F1, N1 probe); MCT200F (with F1 probe), MCT200N (with N1 Probe) |

|

|

Features:

1.

With different external probes, the gauge can be

applied to measuring thickness of non-magnetic coating on magnetic

metal substrate, as well as non-conductive coating on non magnetic

metal substrate. |

|

|

Specifications: 1. Measuring principle: Magnetic induction & Eddy current 2. Measuring range: 0~1250μm, depends on probes. maximum 10mm for the probe F10. 3. Low range resolution: 0.1μm 4. Accuracy: ±(3%Thickness+1)μm, depends on probes and conditions 5. Display: 4 digits LCD with EL backlight 6. Memory for up to 20 files (up to 50 values for each file) of stored values. 7. Unit system: Metric (μm), Imperial (mil) 8. Power source: Two “AA” size, 1.5 Volt alkaline batteries. 200 hours typical operating time (EL backlight off). 9. Communication: USB1.1 10. Dimensions: 125 x 67 x 31 mm 11. Weight:340g |

|

Coating Thickness Meter TIME2600

|

|

Order Number: TIME2600: with F1, N1 probe TIME2600F: with F1 probe TIME2600N: with N1 probe TIME2600F4: with F400 probe TIME2600F19: with F1/90 probe TIME2600CN: with CN02 probe |

|

|

Product

Introduction: TIME2600 Coating Thickness Gauge can nondestructively measure the thickness of non-magnetic coatings (such as zinc, aluminum chrome, copper, rubber, paint and so on) on ferrous metals (such as steel, iron, alloyed metals, hard magnetic steel and so on). It can also measure the thickness of non-conducting coatings (such as rubber, paint, plastic, anode oxide film and so on) on the non-ferrous materials (such as copper, aluminum, zinc, tin and so on). It can fast, exactly and nondestructively measure the thickness of coating and plating. Features 1. Two measuring methods: magnetic induction (F) and eddy current (N). When F probe is equipped, it can measure the non-magnetic coating in magnetism substrate, when N probe is equipped, it measure the non-conductive coating on non-magnetism substrate. 2. 6 types of probes are available for various applications:F400, F1, F1/90, F10, N1, CN02 3. 2 measurement modes: continuous / single 4. 5 statistical ways: Mean values / Max. values / Min. values / testing numbers. (No.) / standard deviations (S.DeV) 5. 640 measured values can be stored 6. Integrated with printer for convenient use 7. Low battery indication 8. 2 switch off modes: manual and auto |

|

| Technical Specification | |

|

1. Standards: DIN,

ISO, ASTM, BS 2. Calibration: Zero and foil calibration 3. Data memory: 640 readings 4. Statistics: Number of measurements, mean, standard deviation, maximum and minimum of 3000 readings 5. Data memory: 640 readings 6. Limits: Adjustable with alarm 7. Interface: RS-232 8. Working temperature: 0~40℃ 9. Power supply: NiMH Rechargeable batteries 1.25V 10. Dimensions: 230 x 86 x 47mm 11. Weight: Approx. 530g |

|

Optional probes and technical specification

| Probe model | F400 | F1 | F1/90º | F10 | N1 | CN02 | |||

| Operating principle | Magnetic induction | Eddy current | |||||||

| Measuring range (µm) | 0-400 | 0-1250 | 0-10000 |

0 to 1250μm 0 to 40μm (for chrome plate on copper) |

10~200 | ||||

| Low range resolution (µm) | 0.1 | 0.1 | 10 | 0.1 | 1 | ||||

| Accuracy | One-point calibration (µm) | ±(3%H+1) | ±(3%H+10) | ±(3%H+1.5) | ±(3%H+1) | ||||

| Two-point calibration (µm) | ±[(1~3)H%+0.7] | ±[(1~3)H%+1] | ±[(1~3)%H+10] | ±[(1~3)%H+1.5] | - | ||||

| Measuring conditions | Min curvature of the min area (mm) | Convex | 1 | 1.5 | Flatten | 10 | 3 | Flatten | |

| Diameter of the min area (mm) | φ3 | φ7 | φ7 | φ40 | φ5 | φ7 | |||

| Critical thickness of substrate (mm) | 0.2 | 0.5 | 0.5 | 2 | 0.3 | unlimited | |||

|

Coating Thickness Meter CM-8855

|

|

1.FEATURES

It meets the

standards of both ISO2178 and ISO 2361 as well as DIN, ASTM and

BS. It can be used both in the laboratory and in harsh field

conditions.

The F probes

measure the thickness of non-magnetic materials (e.g. paint,

plastic, porcelain enamel, copper, zinc, aluminum , chrome etc.)

on magnetic

materials (e.g.

iron, nickel etc.) . often used to measure the thickness of

galvanizing layer,

lacquer layer, porcelain enamel layer, phosphide layer, copper

tile, aluminum tile, some alloy tile, paper etc.

The N probes

measure the thickness of non-magnetic coatings on non-magnetic

metals . It is used on anodizing, varnish, paint, enamel,

plastic coatings, powder, etc. applied to aluminum, brass,

non-magnetic stainless steel, etc.

* Automatic

substrate recognition.

* Manual or

automatic shut down.

* Two measurement

mode: Single and Continuous

* Wide measuring

range and high resolution.

* Metric/Imperial

conversion.

* Digital backlit

display gives exact reading with no guessing or errors.

* Can communicate

with PC computer for statistics and printing by the optional

cable.

* Can store 99

groups of measurements.

* Statistics is

available.

2.SPECIFICATIONS

Display: 4 digits

LCD, backlight

Range:

0~1250μm/0~50mil (other ranges can be specified )

Min. radius work

piece: F: Convex 1.5mm/Concave 25mm; N: Convex 3mm/ Concave 50mm

Min. measuring

area: 6mm

Min. Sample

thickness : 0.3mm

Resolution: 0.1μm

(0~99.9μm); 1μm (over 100μm)

Accuracy: ±1~3%n

or 2.5μm or 0.1mil (Whichever is the greater)

Battery Indicator:

Low batter indicator.

PC interface: with

RS-232C interface

Power supply:

2x1.5 AAA(UM-4) battery

Operating

condition: Temp. 0~50℃ .

Humidity <95% .

Size: 126x65x35

mm; 5.0x2.6x1.6 inch

Weight: about

81g(not including batteries)

Standard

accessories:

Carrying case

...................1 pc.

Operation manual

............ 1 pc.

F probe in built

.................1 pc.

NF probe in

built...............1 pc.

Calibration foils

..............1set.

Substrate (Iron)

................1 pc.

Substrate

(Aluminium)......1 pc.

Optional

accessories: RS-232C cable & software:

1.USB adaptor for

RS-232C

2.Bluetooth interface |

|

|

Coating Thickness Meter CM-8856

|

|

1.FEATURES

It meets the

standards of both ISO2178 and ISO 2361 as well as DIN, ASTM and

BS. It can be used both in the laboratory and in harsh field

conditions.

* The F probes

measure the thickness of non-magnetic materials (e.g. paint,

plastic, porcelain enamel, copper, zinc, aluminum , chrome etc.)

on magnetic materials (e.g. iron, nickel etc.) . often used to

measure the thickness of galvanizing layer, lacquer layer,

porcelain enamel layer, phosphide layer, copper tile, aluminum

tile, some alloy tile, paper etc.

The N probes

measure the thickness of non-magnetic coatings on non-magnetic

metals . It is used on anodizing, varnish, paint, enamel,

plastic coatings, powder, etc. applied to aluminum, brass,

non-magnetic stainless steel, etc.

* Automatic

substrate recognition.

* Manual or

automatic shut down.

* Two measurement

mode: Single and Continuous

* Wide measuring

range and high resolution.

* Metric/Imperial

conversion.

* Digital backlit

display gives exact reading with no guessing or errors.

* Can communicate

with PC computer for statistics and printing by the optional

cable.

* Can store 99

groups of measurements.

* Statistics is

available.

2.SPECIFICATIONS

Display: 4 digits

LCD, backlight

Range:

0~1250μm/0~50mil (other ranges can be specified )

Min. radius work

piece: F: Convex 1.5mm/Concave 25mm; N: Convex 3mm/ Concave 50mm

Min. measuring

area: 6mm

Min. Sample

thickness : 0.3mm

Resolution: 0.1μm

(0~99.9μm); 1μm (over 100μm)

Accuracy: ±1~3%n

or 2.5μm or 0.1mil (Whichever is the greater)

Battery Indicator:

Low batter indicator.

PC interface: with

RS-232C interface

Power supply:

2x1.5 AAA(UM-4) battery

Operating

condition: Temp. 0~50℃ .

Humidity <95% .

Size: 126x65x35

mm; 5.0x2.6x1.6 inch

Weight: about

81g(not including batteries)

Standard

accessories:

Carrying case

...................1 pc.

Operation manual

............ 1 pc.

F probe in built

.................1 pc.

NF probe in

built...............1 pc.

Calibration foils

..............1set.

Substrate (Iron)

................1 pc.

Substrate

(Aluminium)......1 pc.

Optional

accessories: RS-232C cable & software:

1.USB adaptor for

RS-232C

2.Bluetooth interface |

|

|

Coating Thickness Meter CM-8829F, CM-8829N, CM-8829FN

|

|

Operating

principle: magnetic induction / eddy current Measuring range: 0-1250um/0-50mil Resolution: 0.1/1 Accuracy: ±1-3%n or ±2.5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Battery indicator: low battery indicator Metric/ imperial: convertible Power supply: 4 x 1.5V AAA (UM-4) battery Auto power off Operating conditions:0 ~ +45℃ (32℉-104℉), 90%RH max Dimensions: 126x65x27mm weight: 81g (not including battery) Optional accessories: other range 0-200um to 15000um |

|

|

Coating Thickness Meter CM-8829SF, CM-8829SN, CM-8829SFN

|

|

Application:

used for measuring thickness and corrosion of pressure

vessels, chemical equipment, boilers, oil storage tanks etc.

in industries of petroleum, shipbuilding, power station and

machine manufacturing.

With separate

probe(s)

Operating

principle: magnetic induction/eddy current (F/NF)

Measuring

range:0-1250um/0-50mil

Resolution: 0.1/1

Accuracy: ±1-3%n

or ±2.5um

Min. measuring

area:6mm

Min. sample

thickness:0.3mm

Battery indicator:

low battery indicator

Metric/ imperial:

convertible

Power supply:

4x1.5V AAA(UM-4)battery

Auto power off

Operating

conditions:0-+45℃(32℉-104℉),≤90%RH

Dimensions:

126x65x27mm

weight: 81g(not

including battery)

Optional accessories:

other range 0-200um to 15000um

Optional

accessories: RS-232C cable & software:

1.USB adaptor for

RS-232C

2.Bluetooth interface |

|

|

Coating Thickness Meter CM-8828F, CM-8828N, CM-8828FN

|

|

Operating

principle: magnetic induction / eddy current Measuring range: 0-1250um/0-50mil Resolution: 0.1/1 Accuracy: ±1-3%n or ±2.5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Battery indicator: low battery indicator Metric/ imperial: convertible Power supply: 4 x 1.5V AAA (UM-4) battery Auto power off Operating conditions:0 ~ +45℃ (32℉-104℉), 90%RH max Dimensions: 126x65x27mm weight: 81g (not including battery) Optional accessories: other range 0-200um to 15000um |

|

|

Coating Thickness Meter CM-8826F, CM-8826N, CM-8826FN

|

|

Operating

principle: magnetic induction / eddy current Measuring range: 0-1250um/0-50mil Resolution: 0.1/1 Accuracy: ±1-3%n or ±2.5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Battery indicator: low battery indicator Metric/ imperial: convertible Power supply: 4 x 1.5V AAA (UM-4) battery Auto power off Operating conditions:0 ~ +45℃ (32℉-104℉), 90%RH max Dimensions: 126x65x27mm weight: 81g (not including battery) Optional accessories: other range 0-200um to 15000um |

|

|

Coating Thickness Meter CM-8825F, CM-8825N, CM-8825FN

|

|

Operating

principle:

magnetic induction/eddy current (F/NF) Measuring range: 0-1250um/0-50mil Resolution: 0.1/1 Accuracy: ±1-3%n or ±2.5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Battery indicator: low battery indicator Metric/imperial: convertible Power supply: 4x1.5V AAA(UM-4) battery Auto power off Operating conditions:0-+45℃ (32℉-104℉), 90%RH max Dimensions: 126 x 65 x 27mm weight: 81g (not including battery) Optional accessories: other range 0-200um to 15000um |

|

|

Coating Thickness Meter CM-8823

|

|

Operating

principle: eddy current (NF) Measuring range: 0-1000um Resolution: 0.1/1 Accuracy: ±1-3%n or ±2.5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Battery indicator: low battery indicator Metric/ imperial: convertible Power supply: 4x1.5V AA (UM-3)battery Auto power off Operating conditions:0-+45℃(32℉-104℉),≤90%RH Dimensions: 160x68x32mm weight: 250g(not including battery) Optional accessories: other range 0-200um to 5000um |

|

|

Coating Thickness Meter CM-8822

|

|

Operating

principle: magnetic induction/eddy current (F/NF) Measuring range: 0-1000um Resolution: 0.1/1 Accuracy: ±1-3%n or ±2.5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Battery indicator: low battery indicator Metric/ imperial: convertible Power supply: 4x1.5V AA(UM-3)battery Auto power off Operating conditions:0-+45℃(32℉-104℉),≤90%RH Dimensions: 160x68x32mm weight: 250g(not including battery) Optional accessories: other range 0-200um to 15000um |

|

|

Coating Thickness Meter CM-8821

|

|

Operating

principle: magnetic induction (F) Measuring range:0-1000um Resolution: 0.1/1 Accuracy: ±1-3%n or ±2.5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Battery indicator: low battery indicator Metric/ imperial: convertible Power supply: 4x1.5V AA (UM-3) battery Auto power off Operating conditions:0-+45℃(32℉-104℉),≤90%RH Dimensions: 160x68x32mm weight: 250g(not including battery) Optional accessories: other range 0-200um to 15000 |

|

|

Coating Thickness Meter CM-8820

|

|

Operating

principle: magnetic induction (F) Measuring range: 0-2000um Resolution: 0.1/1 Accuracy: ±5%n or ±5um Min. measuring area: 6mm Min. sample thickness: 0.3mm Metric/ imperial: convertible Battery indicator: low battery indicator Power supply: 4x1.5V AA (UM-3)battery Auto power off Operating conditions:0-+45℃(32℉-104℉),≤90%RH Dimensions: 160x68x32mm weight: 210g(not including battery) Optional accessories: other range 0-200um to 15000um |

|

|

Wet Film Combo CM-8000

|

|

Applications: Used for checking the thickness coating of wet paint, enamel lacquer, adhensive, architectural coating, color coating, varnish, chemical industry, or other coating that has been applied to a smooth surface. Specifications: 1. Measuring Range: 25-3000um 2. Step Graduation: 25~400um: 25um; 450-900um: 50um; 1000-1200um: 100um; 1400~3000um: 200um, thickness 1.0mm 3. Measuring Procedure: 1). Select appropriate comb according to approximate known thickness. 2). Hold comb perpendicular to surface coating to be measured. 3). Press into coating until the comb stands square on substrate. 4). Wet film thickness is between the highest step which is coated and the next (higher) step which remains uncoated. |

|

|

Ultrasonic Thickness Gauge TM-8818

|

|

Applications

Used for measuring thickness and corrosion of pressure vessels, chemical equipment, boilers, oil storage tanks etc. in industries of petroleum, shipbuilding, power station, and machine manufacturing. Features: * Using the latest high performance and low power consumption microprocessor technology. * Bidirectional measurement, for materials within measurement range, thickness is measurable with know velocity, Conversely velocity is measurable with know thickness. * Automatic memory material code and sound velocity value, convenient to use. * Coupling symbol indication. * Automatic power off to conserve power. * Use USB data output and RS-232 data output to connect with PC. Specifications: 1. Case Material: Aluminum Alloy 2. Display: 4 Digit LCD 3. Operating Principle: Ultrasonic 4. Measuring Range (metric / Imperial): 0.75~400mm (45# steel, Depend on Probe) 5. Battery Indication: Low Battery Indication 6. Sound Velocity: 500~9,990m/s 7. Lower Limit Steel Pipes: Φ20 x 3.0mm 8. Calibration Block: Included 9. Resolution: 0.01mm / 0.1mm 10. Accuracy: ±0.5%n 11. Automatic memory material code and the value of sound velocity 12. Power off: Auto Power off & Manual Power Off 13. Operating Conditions: Temperature: 0~40 °C, Humidity: < 85 %RH 14. Power Supply: 2 x 1.5V AA Battery 15. Dimensions: 130 x 76 x 31mm 16. Weight: 340g (Not Including Batteries) |

|

|

Ultrasonic Thickness Gauge TM-8816

|

|

Application:

Used for measuring thickness and corrosion of pressure

vessels, chemical equipment, boilers, oil storage tanks etc.

in industries of petroleum, shipbuilding, power station, and

machine manufacturing.

Measuring range

(metric/imperial): 1.0-200mm,0.05-8inch

Operating

principle: ULTRASONIC

Materials

measured: any hard materials, including steel, cast iron,

aluminum, red copper, brass, zinc, quartz glass, polyethylene,

PVC, gray cast iron, nodular cast iron and other materials

Sound velocity:

500-9000m/s

Lower limit steel

pipes: ф15x2.0mm, ф20x3.0mm determined by the transducer

Calibration block:

included

Resolution: 0.1mm

(TM8816C 0.01mm)

Accuracy:

±(0.5%n+0.1)

RS232C interface:

with RS232C

Power supply:

4x1.5V AAA (UM-4)battery

Battery indicator:

low battery indicator

Operating

conditions:0-+45℃(32℉-104℉),≤90%RH

Dimensions:

120x62x30mm

weight: 164g(not including battery |

|

|

Ultrasonic Thickness Gauge TM-8812

|

|

Measuring range:

1.2-225mm, 0.05-9inch Operating principle: ULTRASONIC Materials measured: any hard materials, including steel, cast iron, aluminum, red copper, brass, zinc, quartz glass, polyethylene, PVC, gray cast iron, nodular cast iron and other materials Sound velocity: 500-9000m/s Lower limit steel pipes: ф15x2.0mm, ф20x3.0mm determined by the transducer Calibration block: included Resolution: 0.1mm Accuracy: ±(0.5%n+0.1) RS232C interface: with RS232C Power supply: 4 x 1.5V AAA (UM-4)battery Battery indicator: low battery indicator Operating conditions:0-+45℃ (32℉-104℉), 90%RH max Dimensions: 120 x 62 x 30mm Weight: 164g (not including battery) |

|

|

Ultrasonic Thickness Gauge TM-8811

|

|

Measuring range:

1.2-200mm,0.06-8inch Operating principle: ULTRASONIC Materials measured: any hard materials, including steel, cast iron, aluminum, red copper, brass, zinc, quartz glass, polyethylene, PVC, gray cast iron, nodular cast iron and other materials Sound velocity: 500-9000m/s Lower limit steel pipes: ф15x2.0mm, ф20x3.0mm determined by the transducer Calibration block: included Resolution: 0.1mm Accuracy: ±(0.5%n+0.1) Power supply: 4x1.5V AA(UM-3)battery Battery indicator: low battery indicator Operating conditions: 0-+45℃(32℉-104℉),≤90%RH Dimensions: 160x68x32mm Weight: 208g (not including battery) Optional Accessories: 6MФ6mm thin Material probe: Measuring range (steel): 1.0 50.0mm; Operating temperature: -10~+60℃; 5MФ12high temperature probe: Measuring range (steel): 1.0~225.0mm(normal temperature) Measuring range (steel): 4.0~100.0mm (high temperature) Operating temperature: -10~+300℃ |

|

|

Ultrasonic Thickness Gauge TM-8810

|

|

Measuring range:

1.2-200mm,0.06-8inch Operating principle: ULTRASONIC Materials measured: only 11 types of materials, including steel, cast iron, aluminum, red copper, brass, zinc, quartz glass, polyethylene, PVC, gray cast iron, nodular cast iron Lower limit steel pipes: ф15x2.0mm, ф20x3.0mm determined by the transducer Calibration block: included Resolution: 0.1mm Accuracy: ±(0.5%n+0.1) Power supply: 4x1.5vaa(UM-3) battery Battery indicator: low battery indicator Operating conditions:0-+45℃(32℉-104℉),≤90%RH Dimensions: 160x68x32mm Weight: 208g(not including battery) Optional Accessories: 6MФ6mm thin Material probe:Measuring range (steel): 1.0 50.0mm; Operating temperature: -10~+60℃; 5MФ12high temperature probe: Measuring range (steel): 1.0~225.0mm(normal temperature) Measuring range (steel): 4.0~100.0mm (high temperature) Operating temperature: -10~+300℃ |

|

|

Ultrasonic Thickness Gauge AMA006

|

|

Features: 1. Ultrasonic measures thickness 2. Various material (metal/glass/plastics/pottery and other materials) 3. Ultrasonic velocity adjustable 4. Measuring velocity function 5. Thickness unit mm/inch convertible 6. Coupling indication 7. Build in a metal piece for calibration 8. Low battery voltage indication. 9. Auto power off |

|

|

Specifications:

1. According to European union’s CE safety norms 2. Ultrasonic frequency: 5MHz 3. Digital display: 4 digitals 4. Measuring range: 1.2mm~225mm(steel) 5. Pipe measures: minimum dia. 20*3mm(steel) 6. Velocity range: 1000~9999 m/s 7. Resolution: 0.1 mm. 8. Accuracy: ±(1%H+0.1mm) 9. Response time: 0.5 S 10. Operating temperature: 0~40°C 11. Operating humidity: 10 to 90%RH |

|

Ultrasonic Thickness Gauge AMF018

|

|

*Measuring range:

1.2~220mm (Steel) *Accuracy: ±(1%H+0.1)mm *Resolution: 0.1mm *Sound velocity range: 1000~9999m/s *Working frequency: 5MHz *Minimum limit for tube measuring: Φ20*3mm (Steel) *Auto calibration to assure the accuracy *Auto linear compensation: this advanced software program enhances the precision by correcting the non-linear accuracy of transducer. *Data store/ Data recall/ Data delete function *Sound velocity measurement *Low battery indication *Auto power off *LCD backlight display *Packing Method: Gift box + PP box *Power supply: 3pcs*1.5V AAA alkaline batteries *Weight: 210g *Dimension: 70*145*28mm |

|

|

Ultrasonic Thickness Gauge MT200

|

|

It is designed to

improve safety and ensure reliability of material subject to

corrosion or erosion. Corrosion gauges with their dual-element transducers are the primary inspection tool used to measure the remaining walls of components such as pipelines, pressure vessels, storage tanks, and numerous other applications.. Precision gauges use single-element transducers to provide the thinnest range and highest degree of accuracy possible. Common applications include metals and a variety of non-metals (i.e. glass, ceramic, plastic, etc.). |

| Measuring Range | 0.75mm-300mm(in steel) |

|

| Sound Velocity | 1000~9999 m/s | |

| Resolution | 0.1/0.01mm (selectable) | |

| Units | mm/inch (selectable) | |

| Storage | 20 groups (100 files/group) | |

| Accuracy | ± ( 0.5%Thickness+0.04 ) mm | |

|

Alarm

|

preset upper and lower limit | |

|

Work voltage

|

3V (2 AA alkaline battaries) | |

|

Interface port

|

RS232 | |

|

Dimensions

|

132*76*33mm | |

|

Weight

|

345g | |

|

Display

|

LCD with backlight | |

|

Continuous working period

|

100 hours (with backlight off) |

|

Ultrasonic Thickness Gauge MT160 & MT150

|

|

It is designed to improve safety and ensure reliability of material

subject to corrosion or erosion. |

|

| MT160 | MT150 | |

| Measuring Range | 0.75mm-300mm(in steel) | |

| Sound Velocity | 1000~9999 m/s | |

| Resolution | 0.1/0.01mm (selectable) | 0.1mm |

| Units | mm/inch (selectable) | |

| Storage | 20 groups (100 files/group) | |

| Accuracy | ± ( 0.5%Thickness+0.04 ) mm | |

|

Alarm

|

preset upper and lower limit | |

|

Work voltage

|

3V (2 AA alkaline batteries) | |

|

Interface port

|

RS232, single port and scan | RS232 |

|

Dimensions

|

132*76*33mm | 150*74*33mm |

|

Weight

|

345g | 245g |

|

Display

|

LCD with backlight | |

|

Continuous working period

|

100 hours (with backlight off) | |

|

Multi Function

Ultrasonic Thickness Gauge MT180 & MT190

|

|

Features: The meter is a multi-mode ultrasonic thickness gauge. Based on the same operating principles as SONAR, the instrument is capable of measuring the thickness of various materials with accuracy as high as 0.1/0.01 millimeters. The multi-mode feature of the gauge allows the user to toggle between pulse-echo mode (flaw and pit detection), and echo-echo mode (eliminate paint or coating thickness). Specifications: 1) Display: 4.5 digits LCD with EL backlight. 2) Range: Pulse-Echo mode: 0.65~600mm in Steel. Echo-Echo mode: 3~30mm for MT180, 3~60mm for MT190. 3) Sound Velocity Range: 1000~9999m/s. 4) Resolution: 0.1mm/0.01mm 5) Accuracy: ±0.5% Thickness depends on materials and conditions 6) Memory for up to 20 files (up to 99 values for each file) of stored values. 7) Power Source: Two "AA" size, 1.5 Volt alkaline batteries. 100 hours typical operating time (EL backlight off). 8) Communication: USB 9) Outline dimensions: 150 x 74 x 32mm. 10) Weight: 245g |

|

|

Ultrasonic Thickness Gauge UM-1 and UM-1D

|

| Model |

UM-1 |

UM-1D |

|

| Measuring Range | 0.8 ~ 300mm (P-E) | 0.8 ~ 300mm (P-E) | |

| 3 ~ 18mm (E-E) | |||

| Testing Method | Pulse - Echo (P-E) | Pulse - Echo (P-E) | |

| Echo - Echo (E-E) | |||

| Resolution |

0.001" or 0.1mm |

||

| Units |

inch and mm |

||

| Sound Velocity |

1000~9999 m/s |

||

| Storage |

500 readings |

||

| Interface port |

RS232 |

||

|

Concrete Floor Thickness Tester H51

|

| Application:

The instrument is used for nonmetallic board thickness testing such as concrete, rock, glass etc. The functions include thickness testing, data analysis, saving and transmission. It is a potable, efficient, precise and intelligent instrument. |

|

| Features:

1) Long test distance: Test distance can up to 800mm. 2) High precision and stability: Interpreting the board thickness Intelligently can avoid man-made errors and reduce labor intensity. 3) Fast and efficient: Test 3~5 point thickness within 3 minutes. 4) Long service life of sensor: Improve the service life by paste abrasion resistance allowance on the bottom of sensor. 5) The special clasp between extend bar and transmitting sensor can prevent its falling. 6) Can save test date: This function is convenient for laborer data management. 7) Powerful data process and analysis software in Windows. |

|

| Technical

Data/Measurement 1. Test scope: 40mm~800mm 2. Permissible error: 40 ~ 600mm ±1mm; 601~ 800mm ±2mm 3. Data storage capacity: 3.2 group data 4. Operational environment: temperature:-10°C~+40°C Dampness: <90%RH 5. EMI: no strong electromagnetic field 6. Batteries:6 x AA cells, work more than 30 times |

|

Impact Echo Concrete Thickness Tester H61

|

| Application:

H61 impact echo thickness tester is based on the principle of the impact echo, measuring the thickness of one-side concrete. Mainly used for the thickness of the floor, wall thickness, thickness of tunnel concrete, thickness of pavement concrete, airport runway and other concrete thickness measurement. |

|

| Features:

1. Simple to use. Using the shock wave nondestructive testing, without drilling, coring or other way. 2. Large color LCD screen: 5" color LCD screen display, resolution of 640 x 480, clear and friendly interface. 3. Can display the waveform of impact echo: can directly display the waveform at site, making it easy for the user to observe the impact effect and to ensure the accuracy of the test results. 4. Large storage capacity. Be able to record more than 20000 test point data, convenient for the user. 5. The built-in lithium battery. Instrument use the built-in lithium battery, which is rechargeable. 6. The real USB data transmission. Can rapidly transfer the test data into the computer for further analysis. 7. Can save the test date. Save the test date, convenient for data management. 8. Can be customized in Chinese and English. Can meet the demand of domestic users, but also can satisfy users in overseas markets. 9. Powerful professional windows data analysis processing software: data can be imported into Word and Excel, convenient for post-processing of data. |

|

| Technical

Data/Measurement 1. Measuring range: 5 cm to 110 cm; 2. Test accuracy: <1%; 3. Data storage capacity: can record up to 20000 test data; 4. Display mode: color LCD screen, 640 x 480 resolution; 5. The built-in lithium battery, can use up to 8 hours; 6. Working temperature: - 10 ~ + 50°C; 7. Instrument size: 208 x168 x168 mm; 8. Weight: 960g. |

|

Portable Ultrasonic Flaw Detector

MFD500B

|

|

Display:

Hi-resolution (320×240 pixels) multi-color TFT LCD with 4

user-selectable brightness control provides high contrast viewing of

the waveform from bright, direct sunlight to complete darkness. The

hi-resolution multi-color TFT LCD display with fast 60 Hz update

gives an "analog look" to the waveform providing detailed

information that is critical in many applications including nuclear

power plant inspections. Range: Up to 9999 mm in steel. suitable for use on large work pieces and in high-resolution measurements. Pulse: Pulse Energy selectable among Low, Medium and High. Pulse Width tunable from 0.1µs to 0.5 µs to match the probes with different frequency. Pulse Repetition Frequency adjustable from 10 Hz to 1 KHz in 1 Hz increments. Damping selectable among 100Ω、200Ω and 400Ω for optimum probe Performance: Test Modes include Pulse echo, dual and thru-transmission Receiver: Sampling:10 digit AD Converter at the sampling speed of 160 MHz; Rectification: Positive Half wave, Negative Half wave, Full wave and RF. Analog Bandwidth: 0.5MHz to 15MHz capability with selectable frequency ranges (automatically set by the Gain: 0 dB to 110 dB adjustable in selectable steps 0.1 dB, 2 dB, 6 dB, and locked. instrument) to match probe for optimum performance. |

|

|

Gates: Gate

Start: Variable over entire displayed range Gate Width: Variable from Gate Start to end of displayed range Gate Height: Variable from 0 to 99% Full Screen Height Alarms: Threshold positive/negative Memory: Memory of 100 channel files to store calibration set-up Memory of 1000 wave files to store A-Scan patterns and instrument settings. All the files can be stored, recalled and cleared. Functions: Semiautomatic two point calibration: Automated calibration of transducer zero offset and/or material velocity Flaw Locating: Live display Sound-path, Projection (surface distance), Depth, Amplitude Flaw sizing: Automatic flaw sizing using AVG/AVG or DAC, speeds reporting of defect acceptance or rejection. Digital Readout and Trig. Function: Thickness/Depth can be displayed in digital readout when using a normal probe and Peam path, Surface Distance and Depth are directly displayed when angle probe is in use. Both the DAC and the AVG method of amplitude evaluation are available. Curved Surface Correction feature Crack Height Measure function Weld figure feature Magnify gate: spreading of the gate range over the entire screen width Video Recording and play Auto-gain function Envelope: Simultaneous display of live A-scan at 60 Hz update rate and envelope of A-scan display Peak Hold: Compare frozen peak waveforms to live A-Scans to easily interpret test results. A Scan Freeze: Display freeze holds waveform and sound path data B Scan display feature Real Time Clock The instrument clock keeps running tracking the time. Communication High speed USB2.0 port. The optional DataPro software helps manage and format stored inspection data for high-speed transfer to the PC. Data can be printed or easily copied and pasted into word processing files and spreadsheets for further reporting needs. New features include live screen capture mode and database tracking. Battery: Internal rechargeable Li-ion battery pack rated 7.2V at 8800 mAh; 8 hours nominal operating time depending on display brightness 8-10 hours typical recharge time Knob Operating adjustments are easily and quickly made using the rotary knob. Specifications: Range: 0 to 9999 mm, at steel velocity Material Velocity: 1000 to 9999m/s Display Delay: -20 to 3400 µs Probe Delay/Zero Offset : 0 to 99.99µs Sensitivity: 110 dB max in selectable resolution 0.1, 1.0, 2.0, 6.0 dB and locked. Test Modes: Pulse echo, dual element and thru-transmission Pulser: Tunable Square Wave Pulser Pulse Repetition Frequency ranges from 10 Hz to 1000 Hz Pulse Energy: Low, Medium and High Damping: 100, 200, 400 ohms Bandwidth (amplifier bandpass ): 0.5 to 15 MHz Gate Monitors: Two independent gates controllable over entire sweep range Rectification: Positive halfwave, negative halfwave, fullwave, RF System Linearity: Horizontal: +/-0.2% FSW, Vertical: 0.25% FSH, Amplifier Accuracy +/-1 dB. Reject (suppression): 0 to 80% full screen height Units: Inch or millimeter Transducer Connections: BNC or LEMO Power Requirements: AC Mains 100-240 VAC, 50-60 Hz Dimensions: 263H×170W×61D mm Operating Temperature: -10℃ to 50℃ Storage Temperature: -30℃ to 50℃ |

|

|

Portable Ultrasonic Flaw Detector

MFD350B

|

|

SPECIFICATIONS Range: (0 ~ 6000) mm Bandwidth: (0.5 ~ 10) MHz Material Velocity: (1000 ~ 9999) m/s Dynamic Range: ≥ 32dB Vertical linear error: ≤ 3% Horizontal linear error: ≤ 0.2% Resolution:> 40dB (5P14) Sensitivity Leavings: 60dB (flat-bottomed deep hole 200mmФ2) Rejection: (0 to 80)% Linear Noise level: ≤ 10% Power supply: DC 9V; lithium batteries work for 4 to 8 hours or more Ambient temperature: (-20 ~ 50) ℃ Relative Humidity: (20 ~ 95)% RH Overall dimensions: 263 × 170 × 61 (mm) |

|

|

Portable Ultrasonic Flaw Detector

MFD620C

|

| Specifications 1) Range:0 to 6000 mm, at steel velocity 2) Material Velocity: 1000 to 15000m/s 3) Display Delay: -20 to 3400 µs 4) Probe Delay/Zero Offset : 0 to 99.99µs 5) Sensitivity: 110 dB max in selectable resolution 0.1, 1.0, 2.0, 6.0 dB and locked. 6) Test Modes: Pulse echo, dual element and thru-transmission 7) Pulser: Tunable Square Wave Pulser 8) Pulse Repetition Frequency ranges from 10 Hz to 1000 Hz 9) Pulse Energy: 200V, 300V, 400V, 500V, 600V selectable 10) Bandwidth (amplifier bandpass ): 0.5 to 15 MHz 11) Gate Monitors: Two independent gates controllable over entire sweep range 12) Rectification: Positive half wave, negative half wave, full wave, RF 13) System Linearity: Horizontal: +/-0.2% FSW, Vertical: 0.25% FSH, Amplifier Accuracy +/-1 dB. 14) Reject (suppression): 0 to 80% full screen height 15) Units: Inch or millimeter 16) Transducer Connections: BNC or LEMO 17) Power Requirements: AC Mains 100-240 VAC, 50-60 Hz 18) Operating Temperature: -10°C to 50°C 19) Storage Temperature: -30°C to 50°C |

|

|

Portable Ultrasonic Flaw Detector

MFD650C

|

| *Range: 0 to 9999

mm, at steel velocity *Material Velocity: 1000 to 9999m/s *Display Delay: -20 to 3400 µs *Probe Delay/Zero Offset : 0 to 99.99µs *Sensitivity: 110 dB max in selectable resolution 0.1dB, 1.0dB, 2.0dB, 6.0 dB and locked. *Test Modes: Pulse echo, dual element and thru-transmission *Pulser: Tunable Square Wave Pulser *Pulse Repetition Frequency ranges from 10 Hz to 1000 Hz *Pulse Energy: 200V, 300V, 400V, 500V, 600V selectable *Bandwidth (amplifier band pass ): 0.5 to 15 MHz *Gate Monitors: Two independent gates controllable over entire sweep range *Rectification: Positive half wave, negative half wave, full wave, RF *System Linearity: Horizontal: +/-0.2% FSW, Vertical: 0.25% FSH, Amplifier Accuracy +/-1 dB. *Reject (suppression): 0 to 80% full screen height *Units: Inch or millimeter *Transducer Connections: BNC or LEMO *Power Requirements: AC Mains 100-240 VAC, 50-60 Hz *Dimensions: 280H×220W×70 mm *Operating Temperature: -10℃ to 50℃ *Storage Temperature: -30℃ to 50℃ |

|

|

Portable Ultrasonic Flaw Detector

MFD800C

|

| *Range: 0 to 9999

mm, at steel velocity *Material Velocity: 1000 to 9999m/s *Display Delay: -20 to 3400 µs *Probe Delay/Zero Offset : 0 to 99.99µs *Sensitivity: 110 dB max in selectable resolution 0.1, 1.0, 2.0, 6.0 dB and locked. *Test Modes: Pulse echo, dual element and thru-transmission *Pulser: Tunable Square Wave Pulser *Pulse Repetition Frequency ranges from 10 Hz to 1000 Hz *Pulse Energy: 200V, 300V, 400V, 500V, 600V selectable *Bandwidth (amplifier bandpass ): 0.5 to 15 MHz *Gate Monitors: Two independent gates controllable over entire sweep range *Rectification: Positive half wave, negative half wave, full wave, RF *System Linearity: Horizontal: +/-0.2% FSW, Vertical: 0.25% FSH, Amplifier Accuracy +/-1 dB. *Reject (suppression): 0 to 80% full screen height *Units: Inch or millimeter *Transducer Connections: BNC or LEMO *Power Requirements: AC Mains 100-240 VAC, 50-60 Hz *Operating Temperature: -10℃ to 50℃ *Storage Temperature: -30℃ to 50℃ |

|

|

X-Ray Flaw Detector

General Purpose

|

| Application: Our Portable X-ray Non-destructive Testing Equipments are the ideal inspection instruments used in the field of oil pipeline, chemical, aviation, astronavigation, mechanism, boiler, pressure container, shipbuilding, and national defense industries. Features: 1. An overall self-diagnosis for software and hardware after startup can effectively detect the failure component. 2. Strong anti-interference properties make our X-ray Equipment can also work with electric generator in the wild field. 3. Quickly and exactly set exposure parameters by manual button. 4. High voltage can be started delayed to make enough time for personnel evacuate. 5. Slowly increase and decrease high voltage to protect X-ray generator 6. The ratio of working and rest is 1:1 |

|

|

| Order Number

Serials: XXQ: Directional X-Ray Flaw Detector + Glass Tube XXG: Directional X-Ray Flaw Detector + Ceramic Tube XXH: Weeks to X-Ray Flaw Detector + Flat Target XXHA: Weeks to X-Ray Flaw Detector + Cone Target |

|

Model

|

XXQ-1005

XXH-1005

|

XXQ-1605

XXH-1605

XXG-1605

|

XXQ-2005

XXG-2005

XXH-2005

XXHA-2005

|

XXQ-2505

XXG-205

XXH-2505

XXHA-2505

|

XXQ-3005

XXG-3005

XXH-3005

XXHA-3005

|

XXQ-3505

XXG-3505

XXH-3505

XXHA-3505

|

|||

|

Power supply

|

AC220V+-10% 50Hz

|

||||||||

|

Power (kW)

|

>1.0

|

>1.5

|

>2.5

|

>2.5

|

>3.0

|

>3.5

|

|||

|

Tube voltage (kVp)

|

|

60-160

|

80-200

|

130-250

|

150-300

|

200-350

|

|||

|

Max. Tube current (mA)

|

5

|

5

|

5

|

5

|

5

|

5

|

|||

|

Focal Spot Size mm x

mm

|

Q.G

|

1.0*1.0

|

1.5*1.5

|

1.5*1.5

|

2.0*2.0

|

2.5*2.5

|

2.5*2.5

|

||

|

H

|

1.0*1.5

|

1.0*2.0

|

1.0*2.0

|

1.0*2.4

|

1.0*2.5

|

1.0*2.5

|

|||

|

HA

|

1.0*2.5

|

1.0*3.5

|

1.0*3.5

|

1.0*5.0

|

1.0*6.0

|

1.0*6.0

|

|||

|

Weight kg

|

Tube

|

Q

|

11

|

15

|

20

|

35

|

44

|

44

|

|

|

G

|

|

14

|

20

|

32

|

37

|

37

|

|||

|

H.HA

|

11

|

15

|

20

|

35

|

44

|

44

|

|||

|

Controller

|

11

|

||||||||

|

Radiation angle of

X-ray

|

Q

|

40º

|

|||||||

|

G

|

360º x 25º

|

||||||||

|

H.HA

|

360º x 30º

|

||||||||

|

Max. penetration A3

steel (mm)

|

Q. G

|

8

|

20

|

29

|

39

|

49

|

59

|

||

|

H

|

6

|

18

|

26

|

36

|

46

|

56

|

|||

|

HA

|

|

15

|

24

|

34

|

40

|

50

|

|||

|

Insulation

|

SF6 gas

|

||||||||

|

Environmental

temperature

|

-25℃ ~ +40℃

|

||||||||

|

Relative Humidity

|

No more than 85%

|

||||||||

|

Working conditions of

X-Ray photography

|

1. Focus to Film:

600mm

2. Exposure time: 5

min

3. Film: Tianjin Model

III, intensified by double lead foil.

4. Treatment in the

darkroom: Temp. 20 +/-2ºC, 5 min. blackness ≥ 1.5

|

||||||||

|

Safe working pressure

of gas

|

0.35 ~ 0.50Mpa

(Operation will be prohibited in the case less than 0.35Mpa)

|

||||||||

|

X-Ray Pipeline Crawler

|

| X-ray Pipeline Crawler it is used for welding line inspection. Compared with other testing machine, x-ray machine is more strictly and the result can be kept easily for long terms. It is special designed for pipeline joint inspection project, to assure the quality in pipeline construction. Compared with portable x-ray machine, it is much more automatic and high efficient. |

|

|

Features: Crawler: 1- Electronic speed control technology is adopted to achieve the slow starting and low speed positioning. It can guarantee the x-ray point to face the joint more accurately. 2- Perform very good and won’t be affected by the electric welding machine. 3- It uses multiple real-time function to protect the X-ray generator from water, over-voltage, over current, and overheat. 4- It also has the ability to inspect the energy of battery automatically. The crawler will turn back if the battery is under low power. If no signal, it also returns automatically after 30 minutes. Generator: 1. X-ray system has constant voltage control function to ensure the density of the x ray is consistent ,not impacted by the battery. It also has the ability to save energy and protect the motor from over-current. 2. Safe and reliable generator adopts SF6 gaseous insulator, grounded-anode, and air fan cooling. 3. High purity and high density aluminium radiator is specially designed for our instrument. High temperature installation technology is adopted to improve 30% more heat radiation. 4. The HV coils made by imported enamel wire are applied in the x-ray generator, so as to make the quality of the complete equipment improved a great deal. Battery Panoramic lead-acid battery is selected for our crawler. Compared with the lithium battery, our battery can store energy 30% more. Lead-acid battery can also resist higher temperature, so it can avoid explosion under the overheating condition |

|

| Technical Specifications | |

| Model | XR-S1 | XR-4C | XR-3C | XR-10C |

| Locating System | Magnetic Medium Control (180x120x145mm,1.98kg) | |||

| Available Outside Diameter | 6-12"/159-323mm | 8.6~14"/219~355mm | 12.7~25"/323~630mm | 20~47"/60";508~1400mm (with spindle) |

| Crawler Dimensions | 2930*Φ125mm | 1490x170x150mm | 1300x190x200mm | 1350x240x350mm |

| Position Precision | ±3mm | |||

| Moving Distance | 6km | 5km (Round trip) | ||

| Crawler Weight | 40kg | 37kg | 57kg | 93kg |

| Lead Acid Battery | 9Ah (LI) | 7Ah | 12Ah | 17Ah |

| Battery Weight | 19kg | 28kg | 44kg | 64kg |

| Max Climbing Slope | 10° | 20° | 30° | 40° |

| Turning Radius | ≥10D | ≥7D | ||

| Drive Type | Two Wheels Driven | Four Wheels Driven | ||

| Full charge exposure | 40min | 60min | 90min | |

| Crawling Speed | 15m/min | 18m/min | ||

| Suitable X-ray Generator | 1005L | 1005;1605 | 1605; 2005; 2505 | 2005; 2505; 3005 |

|

X-RAY Generator |

||||||

| Model | 1005L | 1005 | 1605 | 2005 | 2505 | 3005 |

| Max. Penetrate | 8mm | 10mm | 15mm | 30mm | 35mm | 35mm |

| Min Diameter | 125mm | 219mm | 273mm | 323mm | 457mm | 500mm |

| Generator Dimension | 125*940mm | 170*870mm | 200*900mm | 245*910mm | 290*970mm | 310*1070mm |

| Generator Weight | 14kg | 14kg | 18kg | 23kg | 33kg | 39kg |

| Generator Voltage | 100kV | 100kV | 60-160kV | 100-200kV | 150-250kV | 200-300kV |

| Focus Size | 1.0*2.5mm | 1.0*2.5mm | 1.0*3.5mm | 1.0*3.5mm | 1.0*5.0mm | 1.0*6.0mm |

| Radiation Angle | 360° x 40° | |||||

| Exposure Time | 0-5min | |||||

| Anode Target | Cone target | |||||

| Operate Temp. | -20~+75°C | |||||

| Insulation | SF6 | |||||

| Available Humidity | ≤90% | |||||

|

Phased Array Ultrasonic Flaw

Detector CTS-602

|

|

Features: 1. Clear Image 2. Linear Imaging 3. Sector Imaging 4. Accurate Flaw Position and Size 5. Ultrasonic Imaging and A-scan Display Function: 1. Easy operation and user-friendly interface. 2. Conventional and phased array modes are available in the same system, which is convenient for inspectors' testing and evaluation. 3. Up to 32 channels, compatible with 16/32/64/128-element probes. 4. Bi-polar square wave transmission and adjustable transmission pulse width. 5. Transmit single-point focusing and receive dynamic focusing. 6. Featured with linear scanning, fixed-angle linear scanning and sector scanning. 7. A VGA monitor or projector can be connected via the VGA port, good for promotion, demonstration and multi-media teaching for flaw detection training course. 8. Files saved in the system can be exported to a computer for creating reports via the USB port. |

|

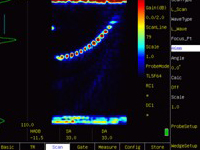

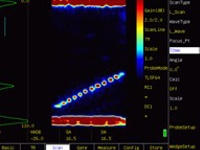

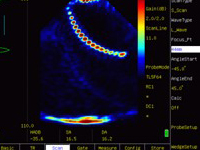

| Phased Array Image Example: | |

| 0°Linear Scan (Longitudinal wave) | -45°~ 45°Sector Scan (Longitudinal wave) | ||

|

|

|

|

| Technical Specifications: | ||

| Function | Conventional | Phased Array |

| System Bandwidth (-6dB) | 0.5~15MHz | 1-10MHz |

| A/D Sampling Frequency | Max 240MHz | 120MHz |

| Probe Connector | 2, BNC or Lemo Connectors | 1, for supporting 16/32/64/128 elements probes, featured with auto recognition |

| Active Aperture | ------ | 2-32, the upper limit depend on the probe element number |

| Pulse Generator | Type: Negative Spike Pulse; Voltage: approx 370V; Frequency: 20-500Hz; Power: Low/High | Type: Bipolar Square Wave Pulse; Transmit Voltage: 20~150V, Step:10V; Pulse Width: 40~500ns, Step: 20ns; Frequency: 100-8KHz; Transmit Delay: 0-20µs; Resolution: 5ns |

| Receiver | Gain: 0-110dB, Step: 0.5/1/2/6/12; Frequency Band (-6dB):1~4MHz/0.5~15MHz; Damping: Low/High; Rectify: Positive, Negative, Full, Filter, RF | Gain: 0-80dB; Frequency Band (-6dB):1~10MHz; Delay: 0~20µs; Resolution: 3.125ns. |

| Focus | ------ | Transmit: Single focus; Receive: 160MHz hardware real time dynamic focus; Max Range: 1008 focus points per scan line. |

| Filter | Auto adjustment based on operating frequency band | Auto adjustment based on probe frequency |

| Scan Type | ------ | Linear/Sector/C/D scan |

| Scan Line | ------ | Linear Scan: Max 256 lines; Sector: Max 128 Lines |

| Scan Angle Range | ------ | Linear: -45°~+45°; Sector: -80°~+80° |

| Scan Range | 0-6000mm (steel longitudinal wave), continuous and adjustable, Min Display Range: 10mm | 0~1000mm (steel longitudinal wave) |

| Material Velocity | 1000~10000m/s | 1000~10000m/s |

| Display Delay | -100~1000mm (steel longitudinal wave) | 0~1000mm (steel longitudinal wave) |

| Probe Zero | 0~200µs | ------ |

| Reject | 0~80 Linear Reject | ------ |

| Curve Function | DAC | ------ |

| Auxiliary Function | A-Scan echo freeze; auto calibration; angle measurement; peak value memory; parameter output; AWS D1.1/D1.5; USB disc storage | ------ |

| Alarm Signal | Sound and Light alarm (build in buzzer and panel LED) | |

| Test Point Selection | Peak Value, Front, J-Front | Peak Value |

| Unit | mm/inch | mm/inch |

| Measurement | 2 Gates: it can measure echo amplitude, sound path, horizontal distance, vertical distance and distance between 2 gates | 2 Gates: it can measure echo amplitude, sound path, horizontal distance, vertical distance and distance between 2 gates; 2 measurements cursors: it can measure horizontal and vertical position and distance between cursors on the image |

| Horizontal Linearity | «0.5% | ------ |

| Vertical Linearity | «3% | ------ |

| Attenuator Error | 12dB ± 1dB | ------ |

| Dynamic Range | »30dB | ------ |

| Far field resolution | »26dB | ------ |

| Electric Noise Level | in initial state, when the detection range and gain are set to maximum, it is «20 (Frequency band 1-4MHz) | ------ |

| EN Norm | EN-12668-1 compliant | ------ |

|

Digital Corrosion Tester AMT810E

|

|

Introduction: AMT810E Portable Fast Electrochemical Corrosion Meter is a simple operation instrument that integrates the Electrochemical Impedance Spectroscopy (EIS) measuring principle and is portable designed for fast measurements and directly display results. EIS measurement is employed to measure the solution resistance (Rs) and the polarization resistance (Rp) and further to calculate the corrosion rate. Applications: 1. Corrosion rate monitor and corrosion inhibitor selection in the petroleum and chemical industry and road and bridge construction site. 2. Metal corrosion rate monitor in oil wastewater, soil, concrete and so on to evaluate corrosion protection countermeasures. Specifications: 1. Probe channels: 1 2. Input impedance: 1011Ω 3. Potential range: ±2.5V 4. Potential resolution: 0.1mV 5. Rs range: 10Ω~500KΩ 6. Rp range: 5Ω~10MΩ 7. Corrosion rate: 0.1um ~ 10mm/a 8. Absolute Measurement Accuracy: <±1% 9. Sine wave amplitude: 1~100mV 10.Sine wave frequency: 10KHz~0.001Hz 11.Timing interval: 1~255h 12.Data storage: 10,000 13.Clock error: ±1min/month 14.Power: AC 220V/DC 1.5V(4 AA cell) 15.Dimensions: 260x165x20mm,Weight:3.5Kg 16.Temperature: -10~50ºC, relative humidity:<80%, away from corrosive gas |

|